When it comes to saving money maintaining your car, changing your own brake pads is one of the best ways. Another thing to consider is whether you should change out just your brake pads or both the brake pads and rotors. Most manufacturers recommend changing the brake pads and rotors at the same time. While we generally agree, if your brake rotors are evenly worn and have sufficient thickness remaining, you can just replace the brake pads.

To perform this DIY, check out this helpful tutorial above from Mike’s Garage. While the video covers a Cayenne S model, the procedure for the 380mm front rotors is virtually identical. Detailed steps can be found below.

Note: This write-up is only for vehicles equipped 380mm front and 358mm rear diameter rotors. This does not apply to vehicles equipped with Porsche Carbon Composite Brakes (PCCB). Before proceeding, please measure your vehicle’s rotors to be sure.

- Mechanic’s Tool Set

- K Tool International Low Profile Jack (3.33 Ton)

- ESCO 10498 Performance Jack Stands (Pair)

- Wheel Chocks

- 1/2 Inch Drive Pivoting Head Ratchet

- 1/2″ Drive Extension Breaker Bar

- 1/2 Inch Drive Click Torque Wrench, 25-250 ft.-lb.

- 1/2-Inch Drive 19MM Non-Marring Lug Nut Socket

- Wheel Bolt Guide For Porsche, Audi, and VW (2 recommended)

- 1/2 Inch Drive Extension Set

- 10-Piece Triple Square Socket Set, Metric 4mm – 18mm

- Torx Bit Socket Set, T10-T60

- Brake Pad Spreader Tool

- Medium Strength Thread Locker

- Loctite Silver-Grade Anti-Seize

- Permatex Ultra Disc Brake Caliper Lube

- PB Blaster Penetrating Oil

- Safety Glasses

- Disposable Gloves

- Respiratory Mask

- FRONT – Brembo OE Equivalent Brake Pad Set - P/N: P65016N

- REAR – Brembo OE Equivalent Brake Pad Set - P/N: P85103N

- FRONT LEFT – Genuine Porsche OE 2 Piece Rotor - P/N: 95535140161

- FRONT RIGHT – Genuine Porsche OE 2 Piece Rotor - P/N: 95535140261

- REAR – Brembo OE Equivalent Rotor - P/N: 09987111 (2 required)

- FRONT – Brake Pad Sensor - P/N: 95561236550 (2 required)

- REAR – Brake Pad Sensor - P/N: 95561236571 (2 required)

- Brake Pad Hardware Kit - P/N: 95535195950 (1 kit required for front)

- Brake Pad Hardware Kit - P/N: 95535295910 (2 required for rear)

Front brake caliper bolts: 200 ft-lbs

13mm brake pad retaining pin: 22 ft-lbs

T50 brake rotor set screw: 10.5 ft-lbs

Rear brake caliper bolts: 133 ft-lbs

Wheel bolts: 118 ft-lbs

Step 1: Prepare your vehicle and work area

- Ensure your car is parked on a flat surface and the brakes are cool.

- Put on eye protection, gloves, and a respirator because brake dust is very hazardous.

- Gather tools and parts.

Step 2: Extract a small amount of brake fluid from the brake fluid reservoir.

- Open the hood and gain access to the brake fluid reservoir by removing the plastic panel on the driver’s side near the windshield cowl.

- Unscrew the brake fluid reservoir cap, remove the mesh filter inside, and extract a little bit of brake fluid using a new turkey baster.

- Check out the video for an overview. While it covers a Porsche 911, after gaining access to the brake fluid reservoir, the process is the same.

- Save this brake fluid in a clean container, so you can re-use it later. If your brake fluid looks dark or contaminated, it is a good idea to also perform a brake fluid flush.

- Reinstall the brake fluid reservoir cap when you are done to prevent debris from getting in.

Step 3: Raise your vehicle off the ground.

- IMPORTANT: If you have air suspension and decided to jack up the car, you will need to lock the air suspension by starting the car and holding the air suspension button up for 10 seconds. You will see an indicator (see photo) pop up on your gauge cluster.

- Unless you are using a vehicle lift, we recommend you raise your car one corner at a time.

- Start by chocking off your wheels to prevent the car from rolling.

- On the corner you will be working on, break the wheel bolts loose but do not loosen them beyond that.

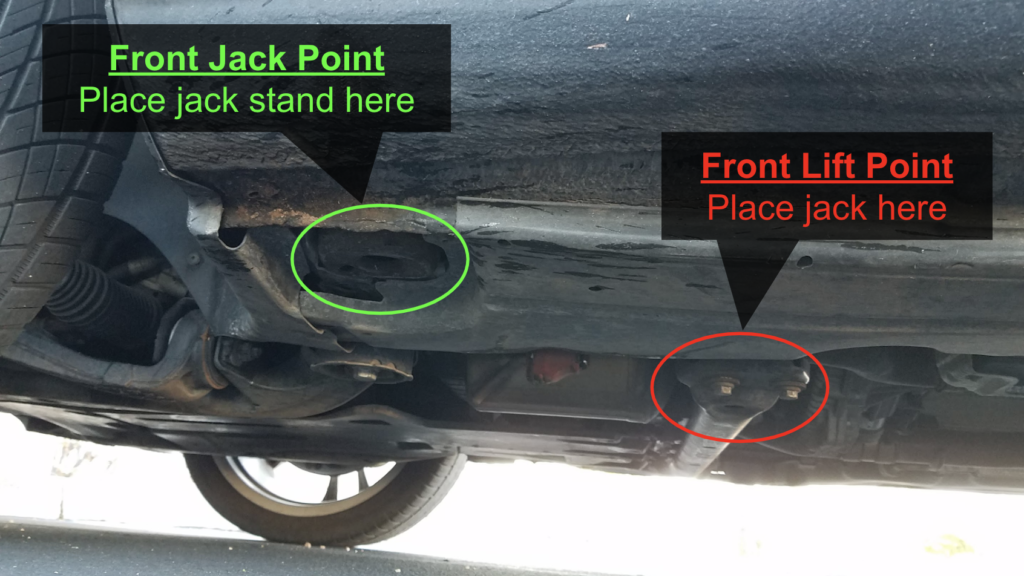

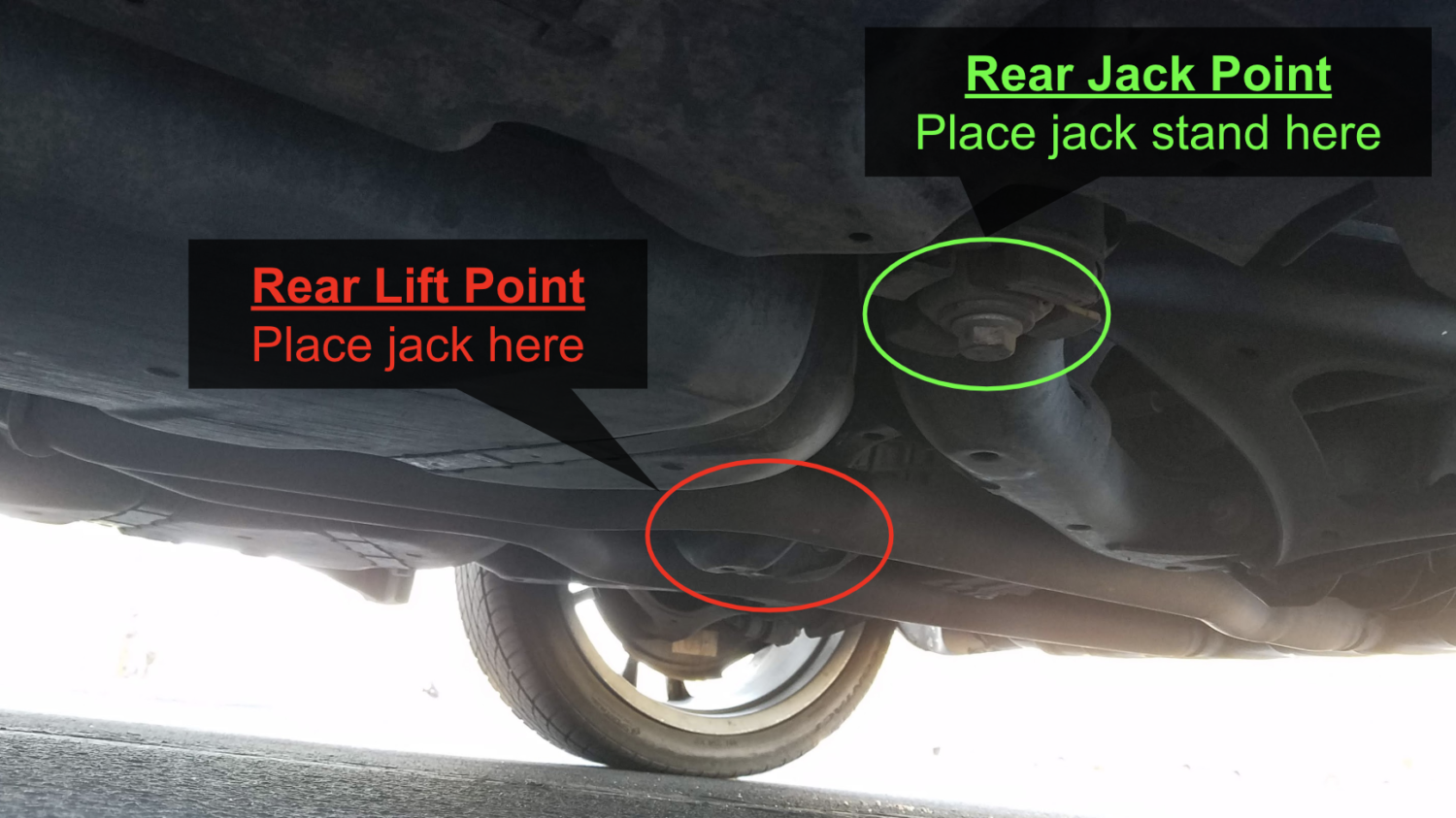

- To get a jack stand on a front jack point, jack the vehicle by the center cross member as shown in the photos.

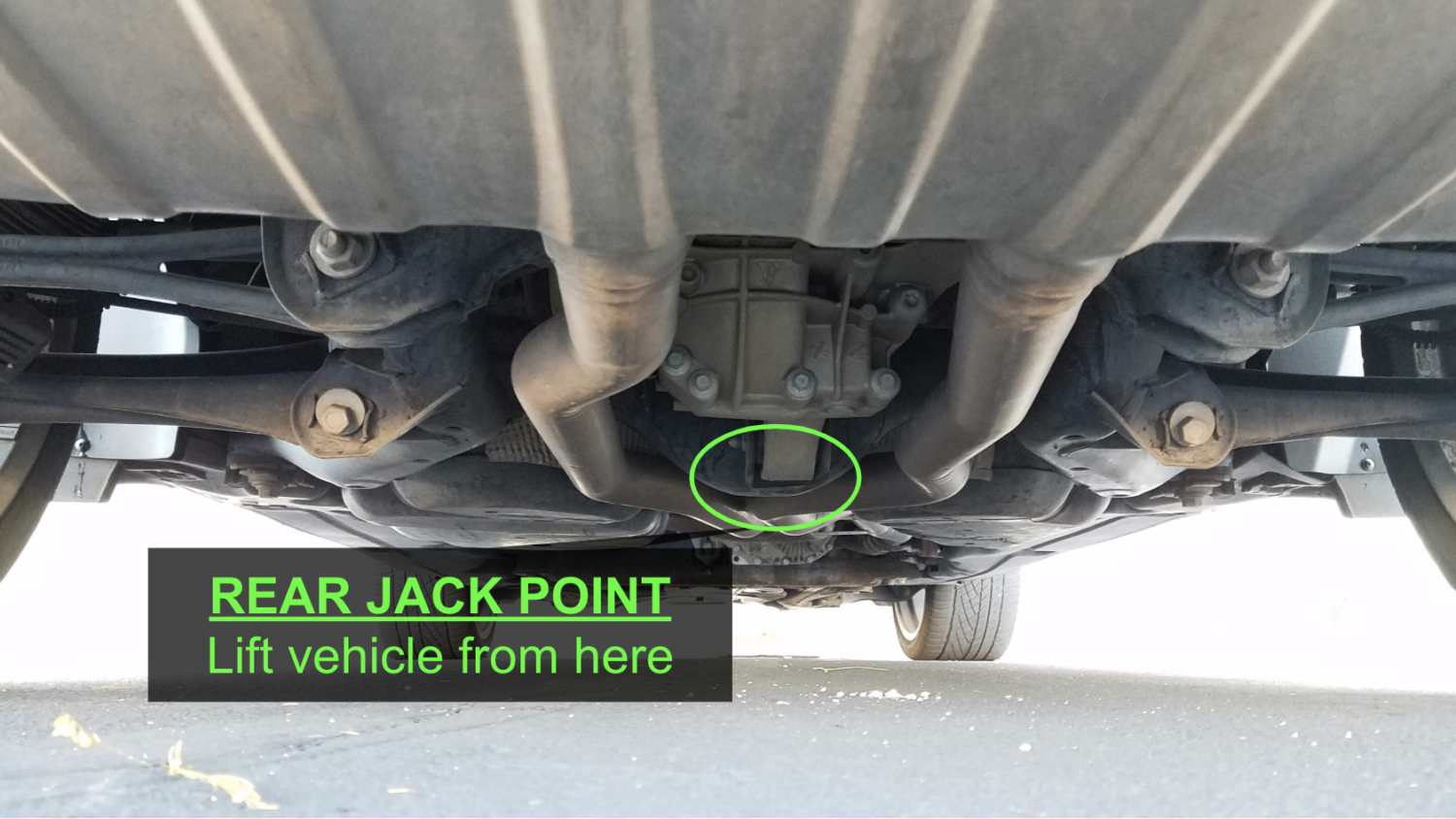

- To get a jack stand on a rear jack point, jack the vehicle up be the rear cross member which is just ahead of the rear differential and in between the exhaust pipes.

- Once raising the vehicle high enough, place a jack stand under the approved jack point and lower the jack until the vehicle rests securely on the jack stand.

- Give the vehicle a hard shove afterwards to ensure it is secure.

- NEVER rely on a jack to support your vehicle.

Step 4: Starting with one of the front corners, gain access to the brakes by removing the wheel

- Remove the wheel using a 19mm socket and breaker bar.

- Place two wheel guide bolts to help you remove the wheel.

- For the front corners, after the wheel has been removed, turn the steering wheel all the way in the direction of the corner you will be working on.

- This will give you enough space to remove the brake caliper bolts.

Step 5: Remove the brake pad spring clip.

- If you are replacing the brake rotors, start by applying WD-40 or another penetrating oil to all the fasteners that hold the brake caliper in place.

- As shown in the first video, remove the pin which holds in the spring clip by using two 13mm sockets and ratchets to unscrew it.

- Using a hammer and a punch or small socket extension, knock the pin out partially.

- While keeping pressure on the spring clip so it doesn’t pop out, use pliers to remove the pin the rest of the way.

Step 6: Remove the brake pads and sensor

- Disconnect the brake pad sensor wiring connector by pressing the plastic tab and pulling down on it.

- Remove the brake bleeder valve cap, so you can move the brake pad sensor wiring out of the way.

- Using a brake pad spreader or small pry bar, spread out the brake pads. This will allow you to pull the brake pads out if the brake rotor has any significant lip on it and allow the new, thicker brake pads to fit.

- Pull the brake pads and sensor out from the caliper.

- Note: If you are only replacing the brake pads, skip to step 10.

Step 7: Remove the brake caliper

- To replace your brake rotor, you will need to remove the brake caliper.

- Take string or bungee cord and tie the brake caliper onto the suspension. This will prevent the brake caliper from hanging by the brake line when you remove the caliper.

- Remove the brake caliper by using a 21mm socket and breaker bar to remove the two caliper bolts.

- Move the brake caliper to the side, so you can remove the brake rotor.

Step 8: Remove the brake rotor

- Remove the brake rotor set screw using a T50 torx bit and ratchet.

- You should now be able remove the rotor.

- If you have difficulty getting it off, apply some penetrating oil to where the rotor meets the hub and use a hammer to lightly tap around the wheel hub area; let the penetrating oil get to work for a few minutes, then use a rubber mallet to loosen the rotor.

- Note: When working on the rear brakes, make sure your parking brake is not engaged or you won’t be able to get the rotor off.

Step 9: Install the new brake rotor and brake caliper

- Clean off the wheel hub with brake cleaner and give it a nice scrub with a wire brush or steel wool.

- Apply anti-seize to where the rotor meets the wheel hub to seizing in the future.

- Place the new brake rotor on the hub.

- Apply anti-seize to the set screw and torque it to 10.5 ft-lbs or just hand tighten.

- Place the brake caliper over the rotor, apply medium strength thread locker to the caliper bolts, and torque them to 200 ft-lbs.

- Note: Porsche states that caliper bolts are single use and new ones should be used each time. If you are going to reuse your caliper bolts, inspect and clean off the threads if necessary to prevent binding or damaging the aluminum upright.

Step 10: Install the new brake pads

- Apply brake lubricant around the edges and back of the brake pads to prevent squealing. DO NOT get any on the surface of the brake pad!

- Insert the brake pads into the caliper.

- Install a NEW brake pad spring clip and insert the retaining pin. If you reuse worn out spring clips, your brakes may squeal.

- Apply medium strength thread locker to the retaining pin bolt and torque it to 22 ft-lbs.

- Insert the brake pad sensors into the brake pads and reconnect the wiring connector.

- Place the wheel back on and tighten the wheel bolts snug in a criss-cross pattern.

- Lower the vehicle off the jack stand.

- Once the wheel is on the ground, torque the wheel bolts to 118 ft-lbs in a criss-cross pattern.

Step 11: Repeat the prior steps on the remaining corners

- The procedure for the rear brake pads and rotors are very similar to that of the fronts, but there are a few differences.

- Most notably, the rear calipers are a “closed” style, so you must remove the brake calipers first before you can remove the brake pads.

- Before removing the brake caliper, relocate the ABS sensor wire which is just held in by a grommet.

- The brake caliper bolts on the rear are more difficult to get to. You will need a 16mm triple square socket, various extensions, and a 1/2″ drive pivoting ratchet (see parts section) or ratchet and universal joint.

- When installing the caliper bolts, torque them to 133 ft-lbs.

Step 12: Clean up your work area and put everything up

- Pro Tip: Don’t throw your brake rotors away. Most recyclers will pay you for your rotors, so get in touch with ones around you.

- Also, brake pads are hazardous to dispose of in the trash. Contact your waste management company and see what steps they recommend.

- Congrats on saving a bunch of money doing-it-yourself!